Woodworking and carpentry are art, and there are many different types of power tools. A radial arm saw vs miter saw is one example. The cordless radial saw and miter saw were designed to ease the process of several woodwork projects. Out of both the power tools, the radial arm saw is more ancient. It transformed the woodwork business when it was created, and many professionals rushed to get their hands on it. While a miter saw is fairly new to the market and has up-to-date technology as compared to a standard radial arm saw.

Miter saws and radial arm saws have a variety of distinctions in common, as they both cut precisely and accurately. They differ, however, in several ways. Due to its greater cutting depth, the radial arm saw facilitates the cutting of thicker wood. A miter saw, on the other hand, is ideal for crosscutting with a fine and accurate bevel on thicker wood. When it comes to deciding between a corded or cordless power tool, most homeowners are caught in the trap of not fully knowing what they need.

Although the radial arm saws are more adaptable and can be utilized in a wide range of woodwork and carpentry tasks, they’ve lately fallen out of favor due to the presence of cutting-edge, modern miter saws utilizing cutting-edge technology. Miter saws, unlike radial arm saws, have safety features that make them safe to use. They are not as hazardous as radial arm saws because they do not contain the same safety standards due to their ease of operation and low risk of harm. Both power tools, on the other hand, are dangerous and must be used following the manufacturer’s instructions.

This article will shed light on the relationships and distinctions between a radial arm saw and a miter so that you may choose which is best for you.

Difference Between a Miter Saw and a Radial Arm Saw

Radial arm saws have greater cutting depths, due to which they are ideal for cutting thicker materials rather than a miter saw. A miter saw is ideal for cutting smaller, but thicker wood pieces. You must utilize every power tool for its intended purpose to improve efficiency and productivity. This is why it’s critical to keep an eye out for early indicators. Although, it will be impossible to ignore them. If you do you’ll endanger yourself.

Unlike miter saws that are portable and light, they may be quickly transferred between different workstations. Radial arm saws are difficult to transport, They also require a station to operate, but they are also bulky and may take up more room.

Radial arm saws are adaptable, as they can make a wide range of cuts, while miter saws have limits on a variety of cuts they can perform. It may be difficult to utilize a miter saw to tear boards lengthwise, for example.

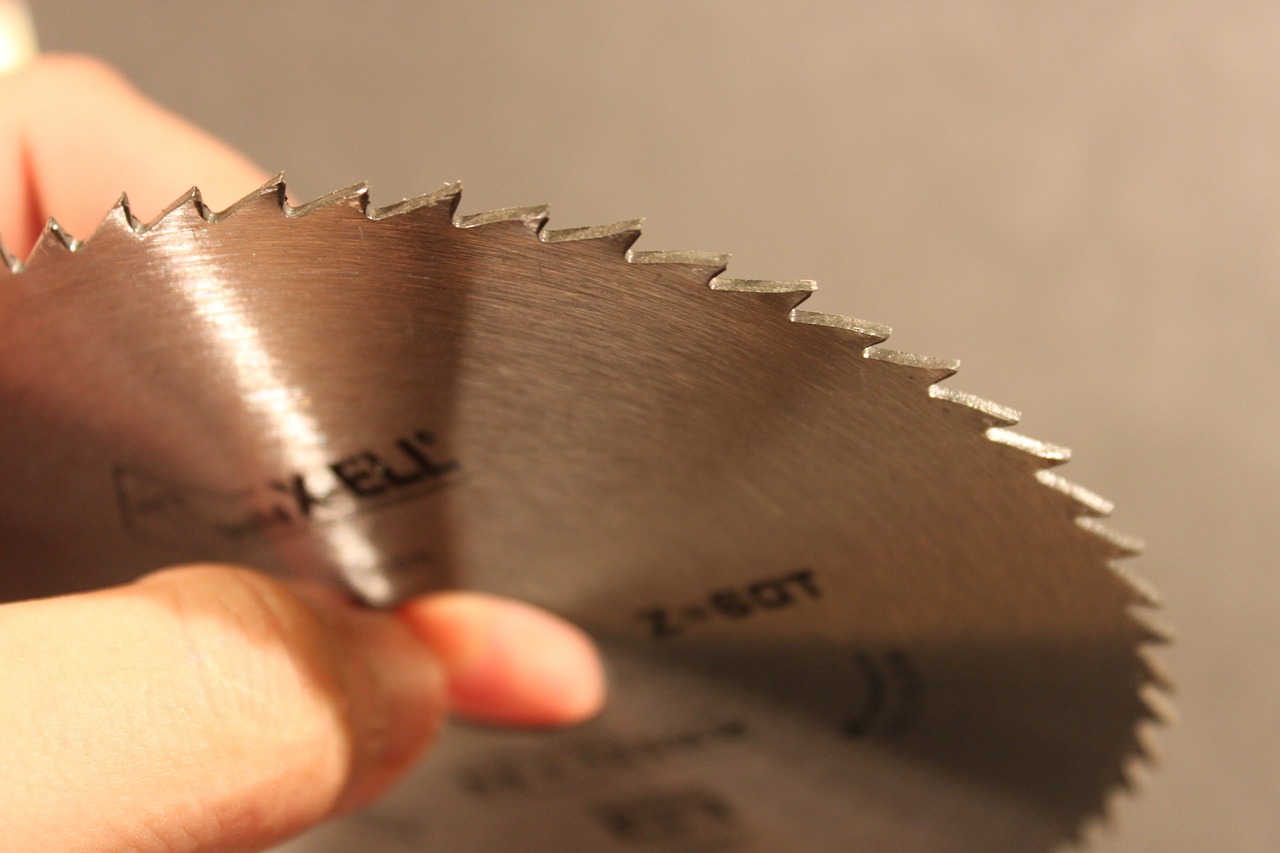

Although a mounted spinning blade is used in both saws to create cuts, the radial arm saw has drawbacks when it comes to safety. These power tools have spinning blades that operate at a high speed. They can be hazardous if not treated with care. Miter saws, on the other hand, feature enhanced safety systems.

Miter saws along with a laser guide are produced by different companies, and radial arm saws exclude this functionality. The laser beam helps the carpenter in making precise and accurate cuts. This equipment eliminates the risk of making mistakes and errors, allowing for clean and tidy workmanship.

What’s the Difference Between a Miter Saw and a Radial Arm Saw?

Choosing the best power tool for your needs depends on several factors, including the type of cutting you’ll be doing. The safety standards for a radial arm saw are quite low, and it is suitable for producing a wide range of cuts and hardwoods. Some individuals may choose to acquire miter saws. Radial arm saws are out of date and may be difficult to compete with miter saws that are designed for accuracy and precision.

If you’re working on a big woodworking job, a radial arm saw may be useful because it can cut various sorts of cuts in wood and timber. However, miter saws are designed specifically to cut at a precise angle, but they cannot be used to rip wood.

Miter saws are not ideal for all types of cuts, but they are more effective due to the advanced technology employed in their construction.

Why radial arm saws are no longer produced?

While there aren’t many radial arm saws at your nearest local big box home improvement store, they are still produced. Although radial arm saws are still utilized in a variety of industrial and commercial settings, they aren’t as popular for domestic usage, and they have never really been. Power tools have long been a part of the home, which has made miter saw and table saw more popular among homeowners. Because they are hazardous and to a certain extent outdated, radial arm saws are less popular nowadays than in the past.

Is the Radial Arm Saw Obsolete?

Over the years, advancements in power tools, which have more efficiency and output of more exact cuts, have revolutionized woodworking and carpentry. Although the radial arm saws are no longer used by woodworkers, they are seldom utilized by amateurs.

Many professionals choose contemporary saws like miter saws since they are more efficient and make work easier. The new power tools are also safer to use than radial arm saws, which expose users to dangers.

Is a Radial Arm Saw a Suitable Alternative to a Table Saw?

While both the saws have similar features in terms of usefulness, radial arm saws are generally superior owing to their greater adaptability for attachments for activities that don’t require cutting, such as drum sanding, routing, and surface planning. Non-sewing attachments are not available on table saws.

In Addition, radial arm saws are simpler to maintain since their overhead blade are easy to align. You can use a radial arm saw on the wall if your workshop has limited space. A table saw, on the other hand, requires a clear path away from the wall so that bigger pieces of work may be moved along the blade.

When it comes to usefulness, most radial arm saws and miter saws have a lot in common. Miter saws are typically more superior owing to the more sophisticated safety features and precise cuts. However, the choice between the two depends upon the demands and preferences of individual users.